Graphene, often hailed as a revolutionary material due to its exceptional strength and conductivity, faces significant hurdles in transitioning from laboratory research to practical applications. A recent study led by Chamalki Madhusha at Monash University proposes a sustainable solution to these challenges by employing a novel, solvent-free method to produce nitrogen-doped graphene nanoplatelets (N-GNPs). The findings were published on December 25, 2025, in the journal ACS Sustainable Chemistry & Engineering.

Challenges in Graphene Functionalization

While pristine graphene demonstrates remarkable properties, its practical use in advanced applications such as smart coatings and conductive composites often requires chemical modifications to enhance dispersibility. Traditional methods of nitrogen doping, which alters graphene’s electronic structure, frequently involve toxic precursors and multi-step processes that generate substantial waste. These conventional techniques can include harsh purification steps and high-temperature treatments, which add to their environmental impact.

Madhusha’s team sought to address these issues by investigating whether advanced materials could be developed without harmful processes. Their research highlights the importance of sustainability in materials science, particularly as industries increasingly prioritize eco-friendly practices.

Innovative Mechanochemical Approach

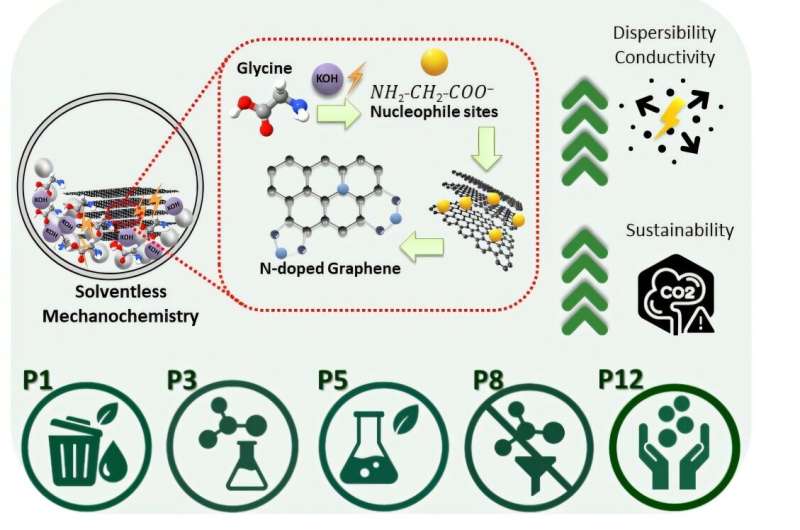

The researchers utilized mechanochemistry, a technique that employs mechanical energy to facilitate chemical reactions without the need for solvents. By using a ball-milling process, they successfully functionalized graphite with a bio-derived nitrogen source—amino acids—under ambient conditions. This innovative method bypasses the need for toxic reagents and high-temperature post-annealing steps, resulting in the production of N-GNPs that combine high electrical conductivity with improved dispersibility.

The study not only focused on the performance of the materials but also on the sustainability of the production process. The N-GNPs achieved a material yield of approximately 80% while demonstrating a significantly lower environmental footprint compared to traditional graphene functionalization methods. The elimination of solvents and energy-intensive steps contributed to a reduced overall energy consumption.

Functional Advantages of Nitrogen-Doped Graphene

Incorporating nitrogen into the graphene lattice enhances various properties, including electrical conductivity and chemical reactivity. The study confirmed that the N-GNPs maintained their structural integrity while gaining functional benefits, making them suitable as nanofillers in composite systems. These enhancements can lead to improved electrical, thermal, and mechanical performance in materials, aligning with the growing demand for high-functioning yet sustainable solutions.

One particularly promising application involves the integration of N-GNPs into vitrimers—polymers that combine the benefits of thermosets and thermoplastics. This compatibility allows for electrically triggered self-healing properties, bolstering mechanical strength and conductivity while ensuring the durability of the material’s structure.

Implications for Future Materials Science

While the study’s focus is on graphene, its implications extend to the broader field of materials science. Many advanced materials still rely on outdated processes that overlook environmental considerations. This research exemplifies how mechanochemical, solvent-free approaches can redefine material production, promoting sustainability without sacrificing functionality.

The findings highlight the potential for industries such as electronics, aerospace, and energy storage to adopt greener manufacturing processes. As regulatory compliance and environmental responsibility become increasingly critical, the integration of sustainable practices in material design is essential for future innovations.

Looking ahead, Madhusha and her colleagues plan to explore how this green synthesis approach can be adapted for other materials and manufacturing processes. The goal is not only to improve material performance but also to develop more efficient and sustainable production methods, paving the way for the technologies of tomorrow.

As the demand for advanced functional materials rises, sustainable synthesis strategies will play a pivotal role in shaping the future of materials science, ensuring that innovation aligns with environmental stewardship.